Material

The bearing’s core components—inner ring, outer ring, and rolling elements—are constructed from high-grade 52100 chromium steel, ensuring exceptional hardness, wear resistance, and dimensional precision to withstand the stresses of micro-scale high-speed rotation. The double metal shields are made of zinc-plated steel, providing robust defense against dust and dry particulate matter while maintaining compatibility with elevated temperatures.

Characteristics

1. Enhanced dust protection for dry environments: The rigid metal shields form an effective barrier against dust, lint, and small dry particles, making it ideal for clean, low-humidity settings such as electronics enclosures or precision instrument housings.

2. High rotational efficiency: The thin, low-friction metal shields minimize resistance, enabling smoother operation at higher speeds compared to rubber-sealed bearings, reducing heat buildup during prolonged use.

3. Temperature resilience: The steel shields and steel body tolerate higher temperatures (up to 110°C), suitable for micro-devices with moderate heat generation from continuous high-speed rotation.

4. Ultra-compact durability: Retaining the miniature dimensions of the MR series, it fits seamlessly into space-constrained assemblies while offering reliable performance under light to moderate radial loads.

Applications

1. Micro-motors: Such as high-speed spindle motors in miniature drones, tiny drive units in model aircraft, and vibration motors in precision haptic devices, where rotational efficiency is critical.

2. Optical equipment: Including lens adjustment mechanisms in compact cameras, mirror rotation components in microscopes, and laser alignment systems, benefiting from dust protection and stable high-speed rotation.

3. Consumer electronics: Like rotating parts in high-speed camera shutters, micro fans in VR headsets, and drive mechanisms in portable scanners, leveraging its low friction and compact design.

4. Precision instruments: Such as gyroscopes in miniaturized navigation sensors, tiny rotating components in analytical devices, and actuators in micro-robotics, where dry-environment reliability and speed are paramount.

| Part Number | MR83ZZ |

| Characteristics |

| System of Measurement | Metric |

| Bearing Type | Ball |

| Seal Type | Shielded |

| Inner Ring Type | Standard |

| For Load Direction | Radial |

| Construction | Single Row |

| Ball Qty | 7 |

| Tolerance Class | ABEC1 |

| Dimensions |

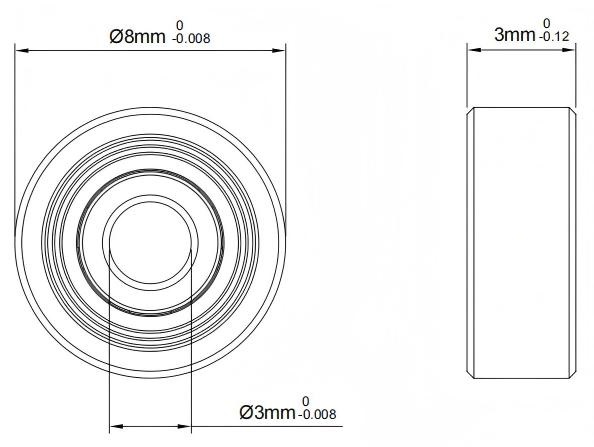

| Bore Dia | 3 mm |

| Bore Dia Tolerance | -0.008mm to 0 |

| Outer Dia | 8 mm |

| Outer Dia Tolerance | -0.008mm to 0 |

| Width | 3 mm |

| Width Tolerance | -0.12mm to 0 |

| Ball Dia | 1.2 mm |

| Radial Clearance | 0.005mm to 0.01 mm |

| Radial Clearance Trade No | MC3 |

| Material |

| Ring Material | Chrome Steel |

| Ball Material | Chrome Steel |

| Cage Material | Carbon Steel |

| Shield Material | Carbon Steel |

| Performance |

| Dynamic Radial Load | 76 lbf |

| Static Radial Load | 25 lbf |

| Max Speed (X1000 rpm) | 60 |

| Temperature Range | -30° to 110 °C |

| Properties |

| Lubrication | Required |

| RoHS | Compliant |

| REACH | Compliant |

| Weight | 0.67 g |