Angular contact ball bearings

Place of Origin: Sichuan, China.

Brand: neutral, TIK or your brand.

Package: plastic bag/box/carton/pallet.

Certification: ISO9001:2015.

Loading Port: Shanghai, Ningbo, Tianjin, Qingdao.

Samples: Free samples are available.

Payment: Western Union, T/T, D/P, L/C.

Quantity in stock: 100,000 pcs.

Request a Quote

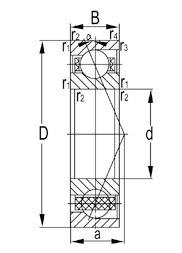

Angular contact ball bearings are particularly suitable for carrying combined (axial and radial) loads. Sometimes, they also can carry pure axial load and operate in higher speed. Under radial load, axial component force will be produced which must be counteracted. So the bearings are normally adjustable against a second bearing. Single row angular contact ball bearings can carry axial load acting in one direction only. In many applications, angular contact ball bearings in pairs or multi-arrangement should be used. The axial load carrying capacity of angular contact ball bearings increases with the increase of contact angle.

Features

Individual bearings of this type are capable of taking radial loads and also axial loads in one direction. Four contact angles of 15°, 25°, 30°, and 40° are available. The larger the contact angle, the higher the axial load capacity. For high-speed operation, however, the smaller contact angles are preferred. Usually, two bearings are used in duplex pairs, and the clearance between them must be adjusted properly.

Pressed steel cages are commonly used, however, for high precision bearings with a contact angle less than 30°, polyamide resin cages are often used.

Applications

These bearings are mainly applied in the machine tool spindles, high-frequency motors, gas turbines, oil pumps, air compressors, printing machines and other installations.

| Bearing No. | Boundary dimensions | Basic load ratings(kN) | Limiting speed | Mass |

| mm | Dynamic | Static | rpm | kg |

| d | D | B | Cr | Cor | Grease | Oil | ≈ |

| 7200C | 10 | 30 | 9 | 5.5 | 2.8 | 22,000 | 28,000 | 0.032 |

| 7201C | 12 | 32 | 10 | 7.9 | 3.8 | 20,000 | 25,000 | 0.037 |

| 7202C | 15 | 35 | 11 | 9.2 | 4.9 | 17,000 | 22,000 | 0.045 |

| 7203C | 17 | 40 | 12 | 10.8 | 5.8 | 15,000 | 20,000 | 0.062 |

| 7204C | 20 | 47 | 14 | 14.5 | 8.1 | 13,000 | 18,000 | 0.100 |

| 7205C | 25 | 52 | 15 | 16.5 | 10 | 11,000 | 16,000 | 0.120 |

| 7206C | 30 | 62 | 16 | 23 | 14.7 | 9,000 | 13,000 | 0.190 |

| 7207C | 35 | 72 | 17 | 30.3 | 20 | 8,000 | 11,000 | 0.280 |

| 7208C | 40 | 80 | 18 | 38.4 | 26.3 | 7,500 | 10,000 | 0.370 |

| 7209C | 45 | 85 | 19 | 40.4 | 29.3 | 6,700 | 9,000 | 0.410 |

| 7210C | 50 | 90 | 20 | 42.8 | 31.3 | 6,300 | 8,500 | 0.460 |

| 7211C | 55 | 100 | 21 | 53.2 | 39.9 | 5,600 | 7,000 | 0.610 |

| 7212C | 60 | 110 | 22 | 61 | 48.2 | 5,300 | 7,000 | 0.800 |

| 7213C | 65 | 120 | 23 | 69.8 | 54.4 | 4,800 | 6,300 | 1.000 |

| 7214C | 70 | 125 | 24 | 72.8 | 59.7 | 4,500 | 5,800 | 1.100 |

| 7215C | 75 | 130 | 25 | 79.2 | 65.6 | 4,300 | 5,600 | 1.200 |

| 7216C | 80 | 140 | 26 | 92.5 | 66.2 | 4,000 | 5,300 | 1.450 |

| 7217C | 85 | 150 | 28 | 99.7 | 84.6 | 3,800 | 5,000 | 1.800 |

| 7218C | 90 | 160 | 30 | 128 | 111.7 | 3,600 | 4,800 | 2.250 |

| 7219C | 95 | 170 | 32 | 134.6 | 112.2 | 3,400 | 4,500 | 2.700 |

| 7220C | 100 | 180 | 34 | 149.1 | 125.4 | 3,200 | 4,300 | 3.250 |

| 7221C | 105 | 190 | 36 | 166.6 | 138.6 | 3,000 | 4,000 | 3.850 |

| 7222C | 110 | 200 | 38 | 184.7 | 154.8 | 2,800 | 3,800 | 4.550 |

| 7224C | 120 | 215 | 40 | 203.1 | 178.4 | 2,400 | 3,400 | 5.400 |

| 7226C | 130 | 230 | 40 | 206.6 | 209.2 | 2,000 | 3,000 | 6.450 |